Working principle of four stroke petrol engine

Working principle of four stroke petrol engine

Bablu Yadav

Posted in Automobile Engineering

.

Introduction

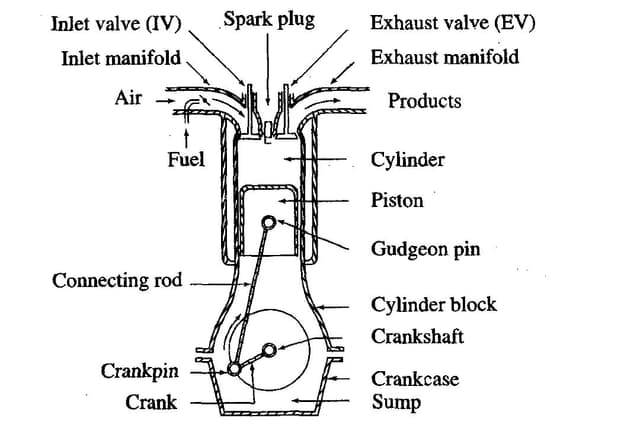

In four stroke petrol engine or Spark ignition engine, all the events of the cycle i.e. Suction, compression, Expansion and Exhaust take place in two revolutions of the crankshaft i.e. 720° of the crank rotation. Thus each stroke is of 180° crankshaft rotation.

Therefore, the cycle of operation for an ideal four stroke engine consists of the following four strokes :

- Induction or Suction or Intake stroke

- Compression stroke

- Expansion or Power or Working stroke

- Exhaust stroke

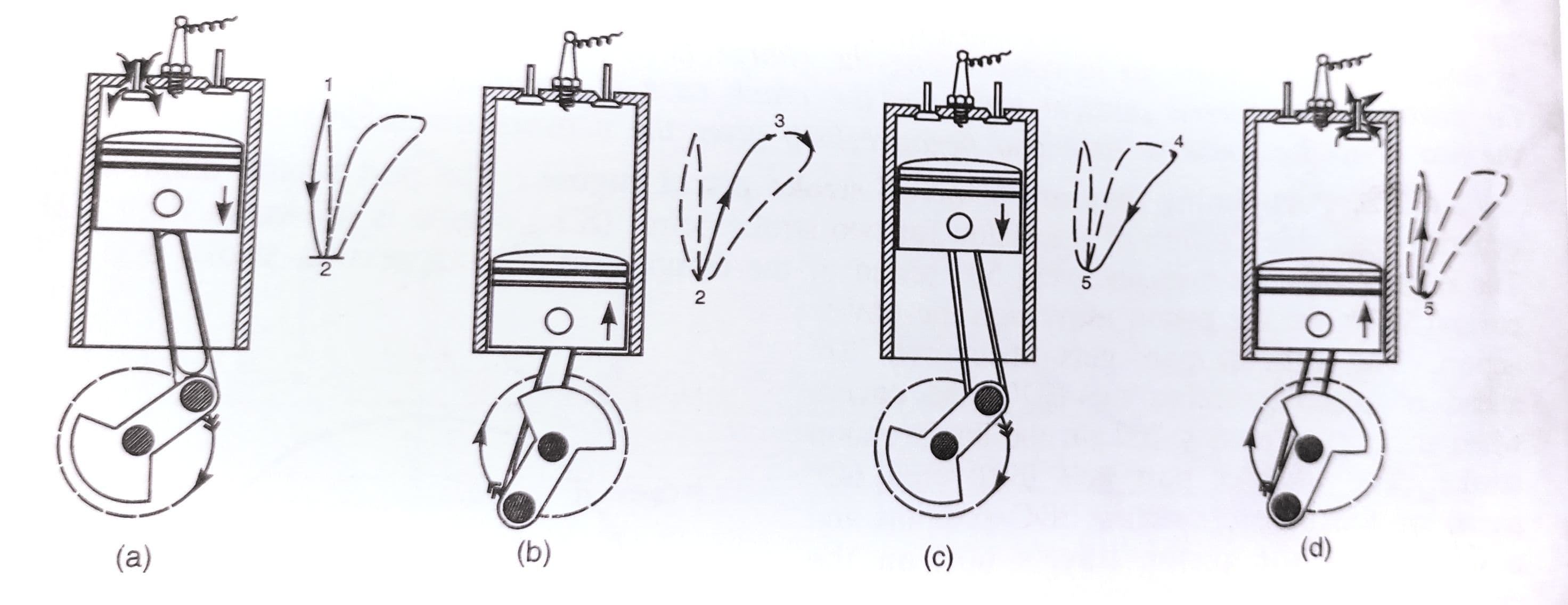

The various processes of the petrol engine with overhead valves are shown in fig a.

(1) Suction stroke :

During the suction stroke,as shown in fig. (a) the piston moves downwards by the crankshaft i.e. from TDC position to BDC position. The crankshaft is initially revolved either by the power generated by the electric starting motor or by the momentum of the flywheel.

The inlet valve opens and the exhaust valve remains Closed. The movement of the piston increases the space, thereby reducing the pressure in the cylinder. The higher pressure of the outside atmosphere forces the charge i.e. air-fuel (petrol air gasoline) through the inlet valve into the cylinder. The operation continues till the piston teaches the BDC position where the inlet valve closes. During this period, the crankshaft rotates through 180° i.e. half revolution.

(2) Compression stroke:

In compression stroke the piston moves from BDC position to TDC position and both the valves (inlet and exhaust) remain closed as shown in Fig. (b). The upward movement of the piston compresses the charge drawn during suction stroke. Due to compression, the pressure and temperature of the air fuel mixture increases continuously and depends upon the compression ratio (normally between 6 and 9). When the piston is just reaching the end of compression stroke, the spark occurs and the charge is ignited at constant volume. The chemical energy of the fuel is converted into heat energy, producing high temperature of about 1800 to 2000°C. The pressure considerably increases.

(3) Power stroke:

The increased high pressure of combustion exerts a greater amount of force on the piston and pushes it downward i.e. from TDC to BDC position with both the valves closed as shown in Fig. (c). This is the only stroke during which, power is produced and thus it is named as power stroke. When the piston reaches BDC position, the exhaust valve opens and the pressure falls to slightly above the atmospheric pressure at constant volume.

(4) Exhaust stroke:

During the exhaust stroke, the exhaust valve opens and the inlet valve remains closed. Pressure of the burnt gases being slightly above the atmospheric pressure, and the piston moves from BDC to TDC position. The upward movement of the piston pushes out the exhaust gases through the exhaust valve or exhaust port into the atmosphere as shown in Fig. (d) and then the next cycle starts.