Working principle of 2-stroke petrol engine

Working principle of 2-stroke petrol engine

Bablu Yadav

Posted in Automobile Engineering

.

Introduction

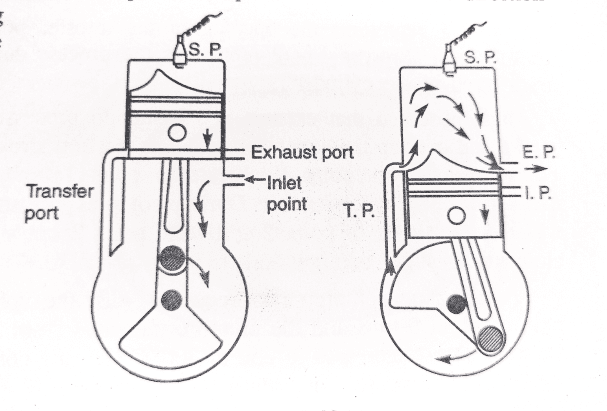

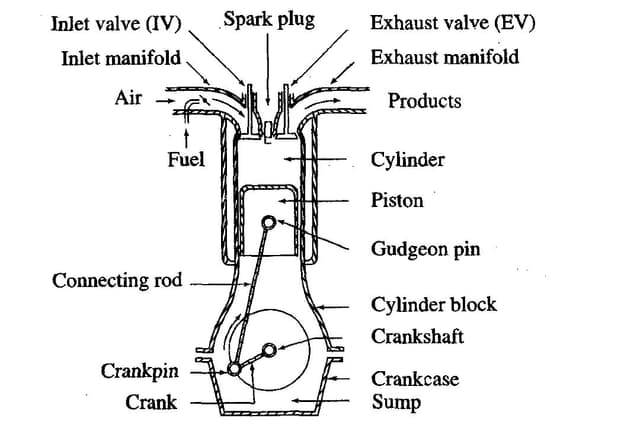

In two stroke petrol engine, there are two strokes of the piston and 1 revolution of the crankshaft to complete 1 cycles. In 2-stroke engines, ports are used instead of valves i.e. suction port, transfer port and exhaust port. These ports are covered and uncovered by the up and down movement of the piston. The top of the piston is deflected to avoid mixing of fresh charged with exhaust gases. The exhaust gases are expelled out from the engine cylinder by the fresh charge of fuel entering the cylinder. The mixture of air and petrol is ignited by an electric is park produced at the spark plug.

The 2-strokes of the engine are

(A) First stroke

(B) Second stroke.

In two stroke petrol engine, the crankcase is made airtight. For the lubrication of the moving parts like crankshaft, connecting rod, cylinder liner and piston, the fuel air mixture mixed with lubricating oil and it is passed through the crankcase and thus these parts are lubricated. This system of lubrication is called petrol lubrication.

(a) First stroke

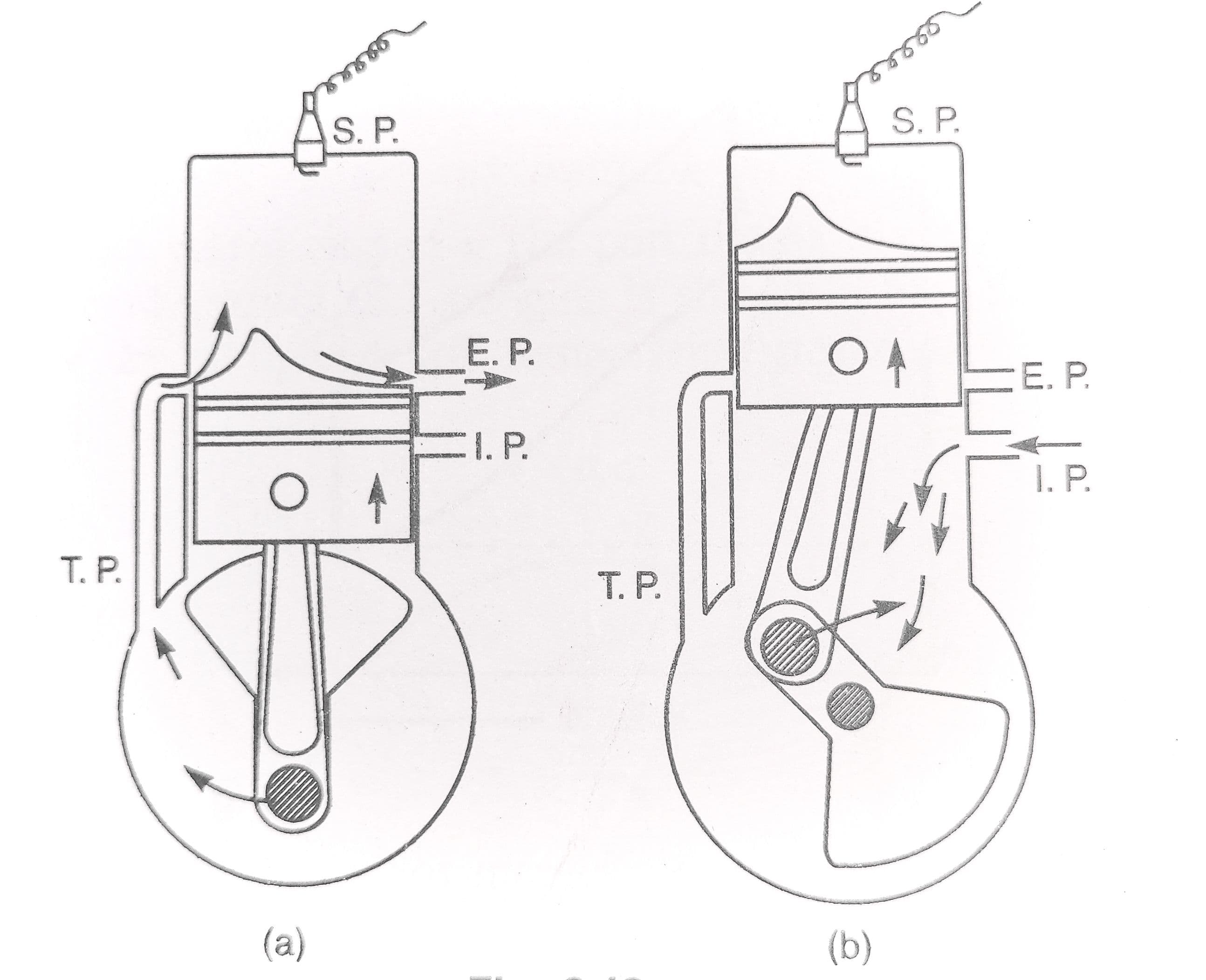

Assuming the piston is at BDC (bottom dead center) position. The inlet port is covered by the piston whereas the transfer port and exhaust port are uncovered. Before piston moves from BDC to TDC (top dead center ), the air petrol mixer enters the cylinder. On the upward movement of the piston, first the transfer port is covered and then immediately after the exhaust port is covered. Simultaneously, the suction or inlet port also gets uncovered. The upward movement of the piston helps to compress the air fuel mixture at the top and creates partial vacuum at the bottom in the crank case. This vacuum gets filled with air fuel mixture from the carburettor by the atmospheric pressure. At the end of the stroke, the piston reaches the TDC position completing the compression stroke as shown in figure- (a) and (b)

(B) Second Stroke:

Just before the completion of compression stroke, the compressed charge is ignited in the combustion chamber by means of an electric Spark produced by the spark plug. Combustion of air fuel mixture pushes the piston in the download direction on the power stroke producing useful work. The moment the power action is over, the exhaust port is uncovered. The exhaust gases escape to the atmosphere. Further movement of the piston covers the inlet port and the fresh charge is compressed in the crank case. Simultaneously, the transfer port is also uncovered. The compressed mixture of air fuel enters the combustion chamber. The deflected shape of the piston avoids the intermixing of the fresh charge and the exhaust gases like the fresh charge rises to the top of the cylinder and pushes out most of the exhaust gases. Thus, the three action; power , exhaust and induction are completed from TDC to Bdc position completing one cycle example two stroke of the piston and one revolution of the crankshaft shown in figure (c) and (d)