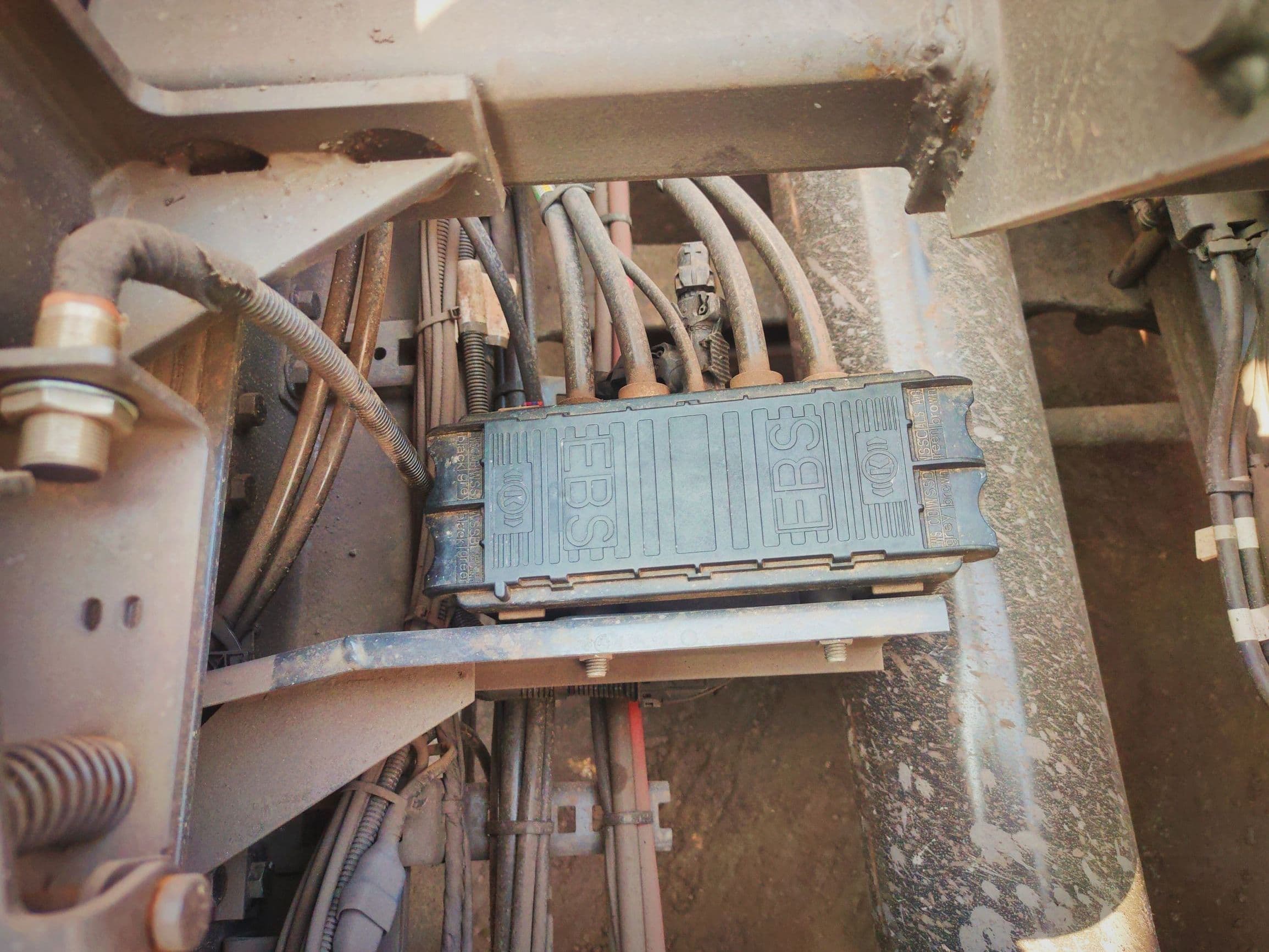

Electronic Brake System (EBS)

The Electronic Brake System is a great achievement in modern automotive engineering. It is a combination of advanced sensors, electronic control, and precise hydraulic or pneumatic control which enables safer and more efficient braking, in today's vehicles.

Bablu Yadav

Posted in Automobile Engineering

.

When it comes to ensuring the safety of a vehicle and its owner, the braking system is very important. The Electronic Brake System is a great achievement in modern automotive engineering. It is a combination of advanced sensors, electronic control, and precise hydraulic or pneumatic control which enables safer and more efficient braking, in today's vehicles. By preventing wheel lockup, optimizing brake force distribution, and enhancing overall stability, EBS gives a great contributions to road safety and driver confidence.Over the years, automotive technology has passed significant advancements, and one such innovation is the Electronic Brake System (EBS).

Understanding the Electronic Brake System (EBS)

The Electronic Brake System, also known as the Electronic Brake Control System (EBCS).

This system is applied by two main types in the vehicle either by:

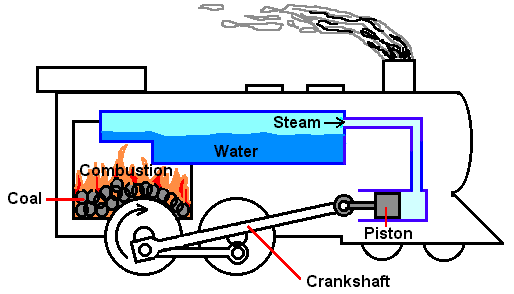

1. Hydraulic Breaking System

2. Pneumatic Braking System

Hydraulic Breaking System

represents an advanced iteration of conventional hydraulic brake systems. It incorporates cutting-edge electronics to enhance braking performance, precision, and overall safety. EBS is primarily comprised of several integral components, each playing a vital role in ensuring effective and responsive braking.

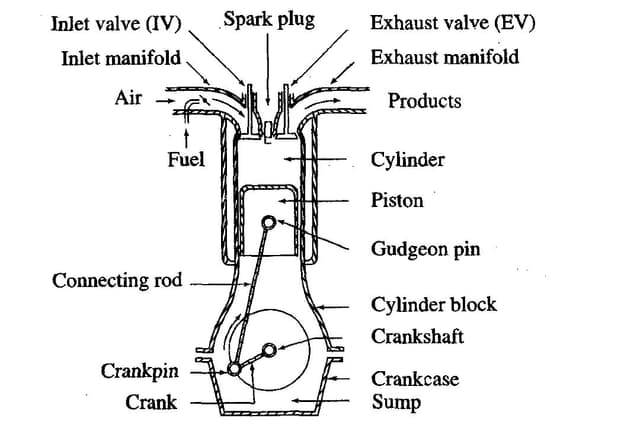

Components of the Electronic Brake System with Hydraulic power are as follows:

1. Sensors:

Sensors stand at the core of the EBS, continually monitoring the vehicle's speed, wheel rotation, and other critical parameters. These sensors offer real-time data to the system, enabling instantaneous adjustments to braking force.

2. Electronic Control Unit (ECU):

Serving as the central processing unit of the EBS, the ECU acts as its brain. It processes data received from sensors and makes determinations regarding the required braking force on each wheel. The ECU can individually adjust brake pressure for each wheel, guaranteeing an optimal traction and stability.

3. Hydraulic Modulator:

Responsible for regulating hydraulic pressure to each wheel's brake caliper or drum, the hydraulic modulator utilizes the information provided by the ECU to control brake pressure at each wheel, presenting precise control of braking force.

4. Actuators:

Actuators are known to convert electronic signals from the ECU into mechanical actions. In EBS, these actuators apply and release the brakes on individual wheels rapidly and accurately, permitting swift adjustments in braking force.

Working of EBS

The working of Electronic Brake System is all about integrating sensor data, the ECU, and precise hydraulic control to enhance braking performance. It aims to prevent wheel lockup, optimize brake force distribution, and maintain vehicle stability during various driving conditions, ultimately providing the driver with a safer and more controlled braking experience.

The EBS operates in real-time, making quick and accurate adjustments to ensure optimal safety and performance.

When the driver presses the brake pedal, it sends a signal to the Electronic Control Unit (ECU) or Brake Control Module.

The ECU continually receives data from various sensors located throughout the vehicle. This data includes information such as wheel speed, vehicle speed, brake pedal force, and more.ABS prevents wheel lockup during hard braking. The ECU monitors wheel speed and if it detects that a wheel is about to lock up, it rapidly modulates the brake pressure by controlling hydraulic valves. This prevents the wheel from skidding, allowing the driver to maintain control of the vehicle.The ECU uses the sensor data to determine the appropriate brake force needed for each wheel, taking into account the driver's input and the vehicle's current conditions. If wheel slip is detected, it will adjust the brake force to maintain traction and stability.The ECU sends commands to the hydraulic modulator, which controls the distribution of hydraulic pressure to each wheel's brake caliper or drum. This ensures that the right amount of brake force is applied to each wheel based on the ECU's calculations.

Functions of the Electronic Brake System:

1. Antilock Braking System (ABS):

A primary function of EBS is ABS, which prevents wheel lockup during intense braking, helping the driver maintain control of the vehicle. This system accomplishes this by modulating brake pressure on individual wheels, effectively averting skidding.

2. Electronic Brakeforce Distribution (EBD):

Another crucial function is EBD, which ensures the equitable distribution of braking force to each wheel, considering variables such as load distribution and road conditions. This enhances stability and control during braking.

3. Traction Control System (TCS):

EBS can also incorporate a Traction Control System, which prevents wheel spin during acceleration by adjusting brake force and engine power, thereby preserving traction on slippery surfaces.

4. Electronic Stability Control (ESC):

ESC, an essential feature for vehicle stability, especially during sharp turns or emergency maneuvers, can selectively apply brakes to specific wheels to prevent skidding or rollovers.