Common rail direct injection fuel system

Common rail direct injection system (CRDI) are employed in modern diesel engines for its optimum performance and improved noise, vibration and harshness.

Bablu Yadav

Posted in Automobile Engineering

.

In diesel engine there are two types of fuel injection system:

1. Air injection system and

2. Airless or solid injection system

In this blog post we are going to learn about the (CRDI) Common Rail Direct Injection System which is under the airless or solid injection system.

Common rail direct injection system (CRDI) are employed in modern diesel engines for its optimum performance and improved noise, vibration and harshness.

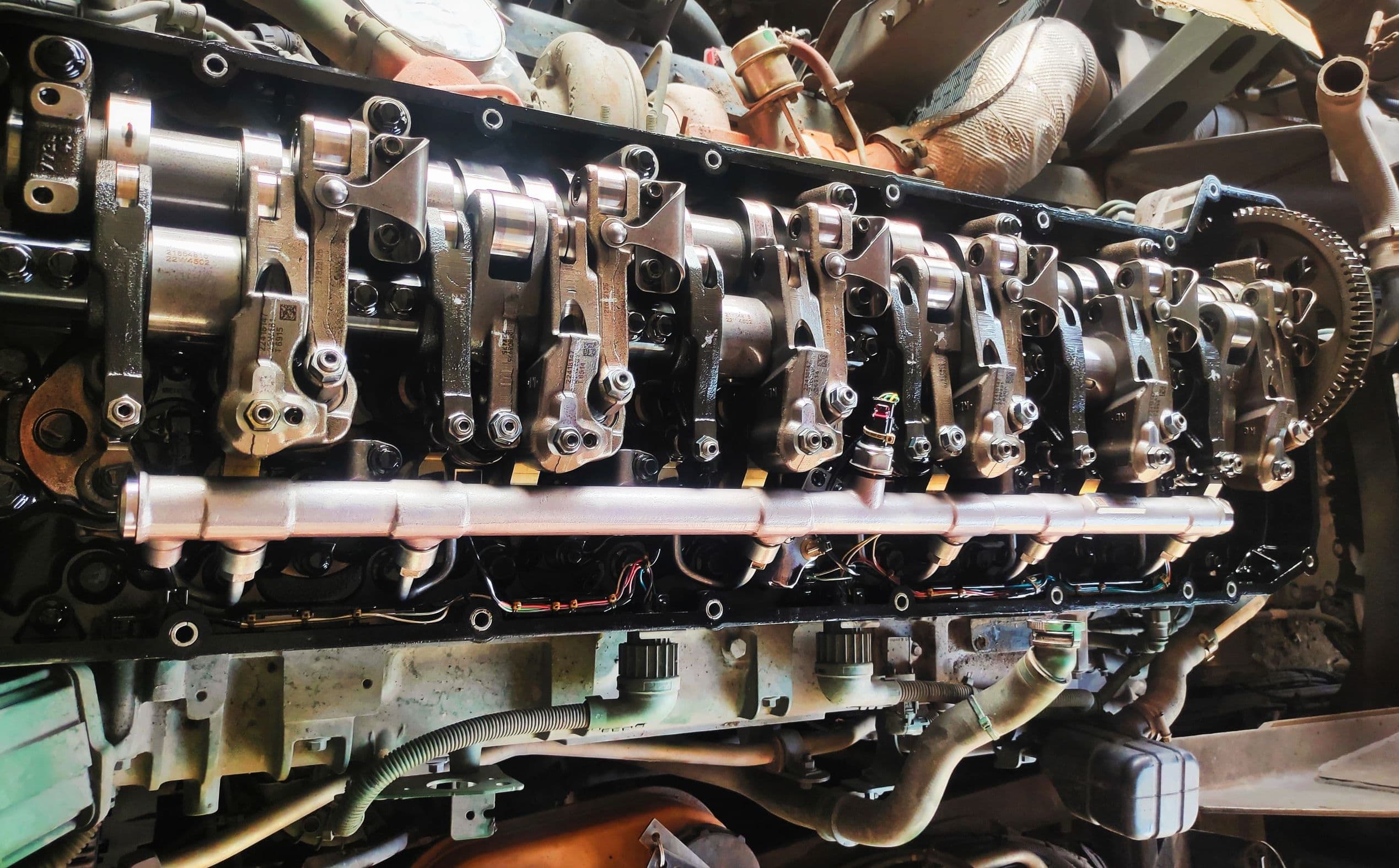

Working of CRDI

Fig.A shows the layout of the common rail direct injection fuel system in this system a single injection pump with injector called as unit injector is fitted and each cylinder the unit injectors are operated by broker arms and springs fitted overhead similar to the engine valves a linkage connects the control racks of all the unit injectors to equalize the fuel injection in all the cylinders.

The feed pump takes fuel from the fuel tank and supplies at low pressure through a filter to all the unit injectors. Relief valve is fitted between the filter and common rail which allows and me access fuel to be returned to the fuel tank.

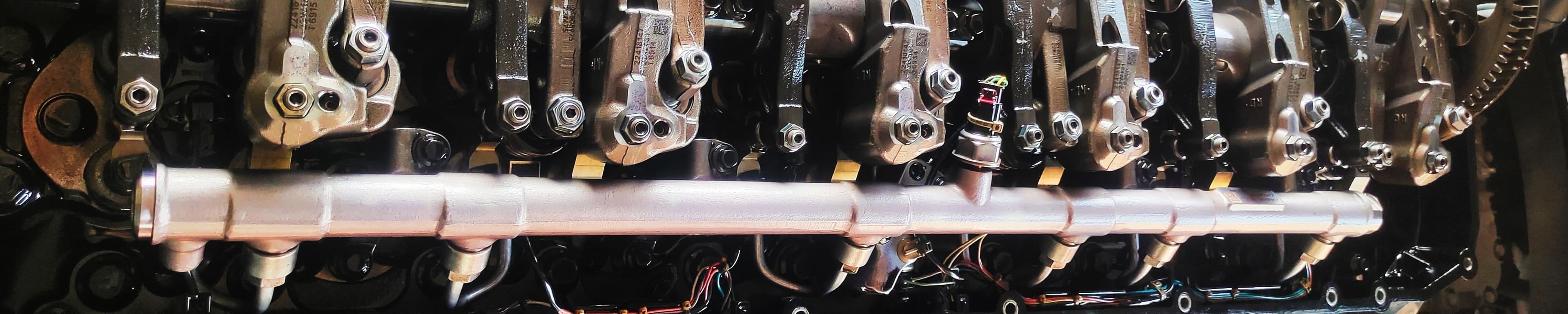

Components of fuel system :

Fig.B shows the layout of components of fuel injection system. For diesel engines the fuel is stored in the fuel tank, the fuel field pump lifts the fuel from the fuel tank and supplies to the fuel injection pump through the filter. The fuel injection pump forces the fuel under a very high pressure to the fuel injector where it is injected into the Indian cylinder in the form of the appropriate instant therefore the complete fuel injection

System consist of the following components :

- Fuel tank

- Fuel feed pump

- Fuel injection pump

- Fuel injector

- Fuel filter

Advantages of CRDI

1. Common rail direct injection system is good for modern diesel engines because of its better fuel economy.

2. Common rail direct injection system creates less pollution and noise for being environment friendly.

3. This system requires only 1 fuel pump for multiple cylinder.

Disadvantage of CRDI

1. Common rail direct injection system cannot be fitted in ordinary engines.

2. High maintenance cost of this engine.

3. Much costly compaired to non CRDI system.