Carburetor

Demystifying the Automobile Carburetor: A Key Component of Fuel Delivery

Bablu Yadav

Posted in Automobile Engineering

.

Introduction

The automobile carburetor has long been an essential component of internal combustion engines or IC engine, playing a vital role in delivering the right fuel-air mixture for optimal combustion. Although fuel injection systems have largely replaced carburetors in modern vehicles, understanding the fundamentals of this historical device remains crucial for automotive enthusiasts and those interested in the mechanics of older vehicles. In this article, we will go with the inner workings of the carburetor, its functions, and its significance in automotive history.

What is a Carburetor?

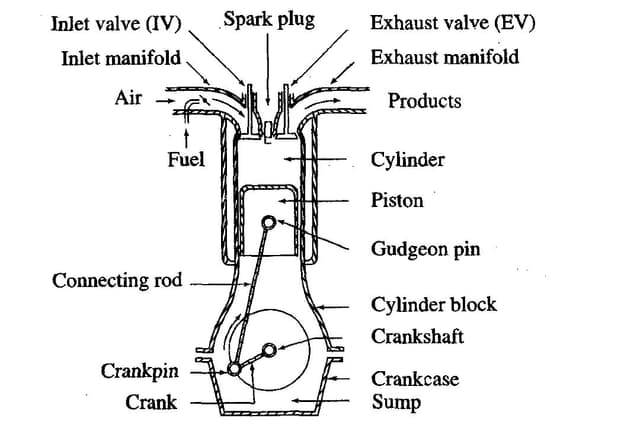

A carburetor is a device which is used in internal combustion engines or IC engine to mix air and fuel in the correct proportions for combustion. It takes in the fuel from the fuel tank and transfers it into tiny particles, combining it with the incoming air before delivering it to the engine cylinders. The carburetor's primary purpose in automotive is to provide the engine with a combustible mixture that allows for efficient and smooth operation.

Components and Operation

A typical carburetor consists of several key components, each playing a vital role in the fuel delivery process. Let's explore these components and their functions:

Air Intake:

The carburetor's air intake is responsible for supplying the engine with the necessary air for combustion. The amount of air flowing into the carburetor is regulated by the throttle valve.

Fuel Bowl:

The fuel bowl is a reservoir that holds the mixture of fuel or gasoline before it is drawn into the engine. It ensures a consistent fuel supply to the engine by maintaining a constant level.

Float Chamber:

The float chamber is connected to the fuel bowl and houses a float mechanism. The float controls the fuel level in the bowl, keeping it at a consistent height.

Venturi:

The venturi is a narrow section within the carburetor where the air velocity increases. This increase in velocity creates a pressure drop, allowing fuel to be drawn into the airflow.

Metering Jets:

These small openings within the carburetor control the fuel flow rate. By adjusting the size of the jets, the carburetor can provide the correct air-fuel mixture for different engine demands.

Choke:

The choke is responsible for enriching the air-fuel mixture during cold starts. It restricts the air intake, increasing the fuel concentration to aid in combustion.

Advantages and Disadvantages

Carburetors were widely used in automobiles for several decades and had their fair share of advantages and disadvantages:

Advantages:

Simplicity:

Carburetors are relatively simple devices, making them easier to understand and maintain compared to modern fuel injection systems.

Cost-Effective:

Carburetors are generally less expensive than fuel injection systems, which contributed to their widespread use in the past.

Compatibility:

Carburetors can work with a wide range of fuels, including gasoline, ethanol blends, and certain alternative fuels.

Disadvantages:

Fuel Efficiency:

Carburetors are less efficient than modern fuel injection systems(FI engine) when it comes to delivering the optimal air-fuel mixture. This can result in lower fuel efficiency and increased emissions.

Performance Limitations: Carburetors can struggle to provide precise fuel delivery for high-performance engines, limiting their use in sports cars and racing applications.

Cold Start Challenges:

Achieving the correct air-fuel mixture during cold starts can be problematic with carburetors, leading to difficulties in starting the engine in cold weather.

The Transition to Fuel Injection

Over time, advancements in technology led to the development of electronic fuel injection (EFI) systems, which gradually replaced carburetors in modern automobiles. Fuel injection systems offer more precise fuel delivery, resulting in improved fuel efficiency, reduced emissions, and betters engine performance.